| Strategic Aspects of Purchasing Strategy |

What to Consider: |

| Role and Scope of Purchasing Responsibility |

- How should purchasing contribute to solidifying the company’s competitive position? Should it, in accordance with the company strategy, ensure timely deliveries or is the main goal to lower costs? Or are the technical parameters and quality of deliveries the main barometer of success?

- What should the scope of purchasing activities be? What activities should the purchasing department carry out? Should it only be involved in the supplier selection process, orders and deliveries of goods and services, or also be responsible for quality, contracts, planning and finance?

- Would it be beneficial to include it in other aspects of company management? If so, how? Can it, for example, play a role in product development? If so, how?

|

| Purchasing Management, Organization and Structure |

- Purchasing in companies is usually carried out in cooperation with a number of other areas of business – it can be the recipient, for example when the logistics, quality control, finance or legal departments provide services to the purchasing department. In other cases, certain departments are highly dependent on the purchasing department – i.e. development, planning, production, maintenance, projects, and sales. What will then be the purchasing department’s position in terms of the company’s organizational structure and management?

- Will purchasing be centralized, or will individual departments make purchases themselves with the assistance of the purchasing department?

|

| Selection and Development of Supplier Networks |

- Who are our suppliers?

- How will we utilize our suppliers, taking into account the diversification of strategic dependence risks, supplier substitutability, price optimization, supplier quality (esp. is the supplier capable of making deliveries in the given time-frame, volume and quality) etc.?

- Which criteria or set of criteria will we consider when selecting suppliers with regard to the company strategy (e.g. a cost-sensitive strategy will require focusing on making low-cost purchases, differentiation strategies aimed at quality, on the other hand, will require focusing on the required level of quality necessary for market entry)? Key criteria may include (text below adapted from Červený, Hanzelková, Keřkovský, Němeček, 2013):

- Price – If all of the requirements regarding product specifications and delivery conditions have been met, price is one of the main criteria. When evaluating the price, it is advisable to consider hidden costs (qualification costs, poor quality, delays, extra work, monitoring suppliers, time spent problem-solving etc.).

- Payment Conditions – Suppliers with longer payment due dates are preferable (e.g. 90 days and more) – lowering operating capital costs.

- Helpfulness and Communication– Often overlooked criteria which is in fact crucial for long-term cooperation and continuous improvement.

- Technical Skills– Does the supplier meet all of your requirements? Are they well-equipped, well-staffed and experienced?

- Capacity – Is the supplier capable of delivering the entire quantity? Are our volumes enticing for suppliers? Certain companies consider it best to utilize 5 – 20% of the supplier’s capacity. If the orders make up more than 20% of the supplier’s total sales, both sides become excessively dependent on one another.

- Agreement with Standard Purchasing Conditions – Suppliers who do not require modifications to be made to standardized contracts are preferable.

- Ethical Aspects – Does the supplier uphold occupational safety and health regulations and environmental protection regulations? Does the supplier respect basic ethical aspects of business?

- The Supplier’s Financial Situation – Is the supplier financially stable? For this purpose, we can take advantage of analyses conducted by rating agencies, or simply consult publicly available resources (internet) to verify information about the company etc.

- Management System – Has the supplier implemented a management system? Is the supplier certified according to international ISO or other standards?

- Range of Activities – Does the supplier have its own development, laboratory, service team etc.?

- Innovation Potential – Does the supplier have sufficient innovation potential so as to be able to respond to changing demands and needs in the market?

- Export and Global Capability– is the supplier capable of providing delivery services for all of our business activities or company branches in different markets?

- Market Share, Reputation and Other Customers – is the supplier capable of delivering the necessary materials, goods or services in the required volume, quality and amount of time? Is the supplier professional and reliable with positive reviews from other credible customers?

|

| Planning and Managing Deliveries and Stock |

- Are our current stock levels adequate, meaning there are not any shortages or surpluses with respect to production requirements?

- Is production based on stock or on orders? How high should the volume of our stock be?

- How will we approach different types of inventory – materials, finished products, services or others?

- How will we ensure the delivery of materials and services to places of consumption – what will our preferred delivery conditions be, including mode of transport, packaging, who will provide storage – our company, our supplier or the delivery service etc.

- What will the cost of shipping be versus the cost of storage and production interruption? In light of these costs, what will be the optimal frequency, size and speed of deliveries and what targets will be set for stock volumes?

|

| Information and Technology Purchasing Support |

- Would it be beneficial to have an information system for purchasing and logistics management which could contribute to speeding up and simplifying transactions, eliminating human error in the ordering process, arranging and receiving deliveries, or eliminating subjective decisions in the purchasing process?

- If so, will purchasing be carried out using independent software?

- Which functions should this SW (system) perform? It usually ensures the following (text below adapted from Červený, Hanzelková, Keřkovský, Němeček, 2013):

- Creating, approving and receiving orders,

- Receiving, approving and paying invoices from suppliers,

- Managing price and quantity errors,

- List of approved suppliers,

- Reporting costs of purchased materials and services,

- Monitoring delivery schedules,

- Monitoring and resolving quality errors including statistical processing,

- Material demand forecasting,

- Managing long-term contracts and call-offs,

- Creating purchasing catalogs with the option of ordering standard materials,

- Electronic demand management including electronic auctions,

- Supplier assessment based on various criteria,

- Sharing data with suppliers electronically (specifications, plans, bill of materials, changes),

- Integrating the information system for managing stock, purchasing and logistics into one planning unit.

|

| Identifying and Managing Purchasing Risks |

- What are the major risks associated with purchasing in terms of the overall strategy, and how can they be handled? It is advisable to consider whether or not you face the following risks (text below adapted from Manuj, Mentzer, 2008):

- Financial risks – e.g. additional costs, exchange rate fluctuations, increase in commodity prices, failure to deliver pre-paid goods etc.

- Delivery and transport risks – e.g. delays, additional costs, damages, delays at customs, loss;

- Legal risks – contract violations, customer complaints, patents and intellectual property, mandatory certificates etc.

- Risks associated with human health and the environment – e.g. injury, damage to private property, unauthorized transportation of hazardous materials;

- Geopolitical risks – changes in local legislature, loss of ownership of goods, termination of contracts, license revocation etc.

- Organizational and HR risks- changes in accountability in contracted companies, changes in strategy, departure of key members etc.

|

| Quality Control and Management of Deliveries |

- What criteria will we use to assess the quality of deliveries? During which part of the delivery process will quality control take place? Who will conduct quality control and who will be held responsible? Will we perform continuous checks as well as entrance and exit checks?

- Will we implement a complex quality management system? If so, how will the basic parameters be set up, such as (text below adapted from Červený, Hanzelková, Keřkovský, Němeček, 2013):

- Requirements, selection and approval of suppliers,

- Qualifications of suppliers and their products,

- Monitoring, assessment and development of suppliers,

- Supplier audits and internal audits,

- Disposition to qualitative errors and conflicts,

- Corrective measures and continuous improvement etc.

|

| Contractual Relationships and Legal Obligations |

- Which contractual terms will be most beneficial to the company and why? What are some potential legal risks that must be addressed in terms of the purchasing process?

- Which types of legal documents should the company use with respect to purchasing management? For example (text below adapted from Červený, Hanzelková, Keřkovský, Němeček, 2013):

- One-off orders, open orders and long-term contracts, ,

- Terms of delivery (customer) and conditions (supplier),

- Non-disclosure agreements,

- Contractual service agreements,

- Lease agreements,

- Insurance (goods and delivery),

- Warranties and liability agreements,

- Commercial codes for pertinent countries,

- Tax and customs legislation,

- Certificate of origin,

- Safety regulations and environmental protection laws,

- Economic competition laws,

- Various trade and export restrictions, embargos etc.

- Does your company prioritize negotiating lower prices over minimizing risk? Are one-off orders more favourable than long-term contracts?

- Do the delivery terms and conditions clearly define all relevant aspects so that the supplier cannot change the price, specifications, delivery date, quality, mode of transport, rate, but also conflict resolution, compensation due to failure of rendering services as per the agreed terms and conditions etc.?

- Have you implemented a risk treatment plan (Červený, Hanzelková, Keřkovský, Němeček, 2013) in relation to standards and regulations for import/export (customs or certification requirements etc.), as well as who will manage these risks (smaller companies may consult specialized external companies e.g. export insurance companies, customs brokers, certification agencies, auditing firms etc. experienced in the selected field in the given country etc.)?

|

| Financial Aspects of Purchasing |

- Produce/implement alone or purchase? Deciding on the basis of financial (cost) as well as non-financial factors, such as whether or not (text below adapted from Červený, Hanzelková, Keřkovský, Němeček, 2013):

- Producing products yourself or purchasing them is in line with your long-term business strategy,

- Producing products yourself is one of your company’s key competencies,

- The product or service is relatively accessible from multiple sources,

- It is possible to secure your own trade secrets, patents etc. when entrusting a third party with your product or service.

- What impact should purchasing have on the variable costs that are affected during the purchasing process:

- Purchase price negotiated with the supplier;

- Volume discounts and rebates;

- Delivery terms and conditions;

- Exchange rate fluctuations;

- Delivery and storage costs;

- Costs to ensure the quality and timeliness of the delivery;

- Projects aimed at reducing costs and increasing supplier productivity;

- Increasing organizational productivity during the purchasing process.

- What impact should purchasing have on fixed costs, determined by:

- Investment costs;

- Payment conditions;

- Utilization of a facility’s capacity;

- Training, maintenance and service costs.

- How are cash flow and working capital affected in terms of:

- Payment conditions for suppliers;

- Length of delivery dates;

- Size and cost of raw material inventory;

- Qualification rate of new suppliers.

|

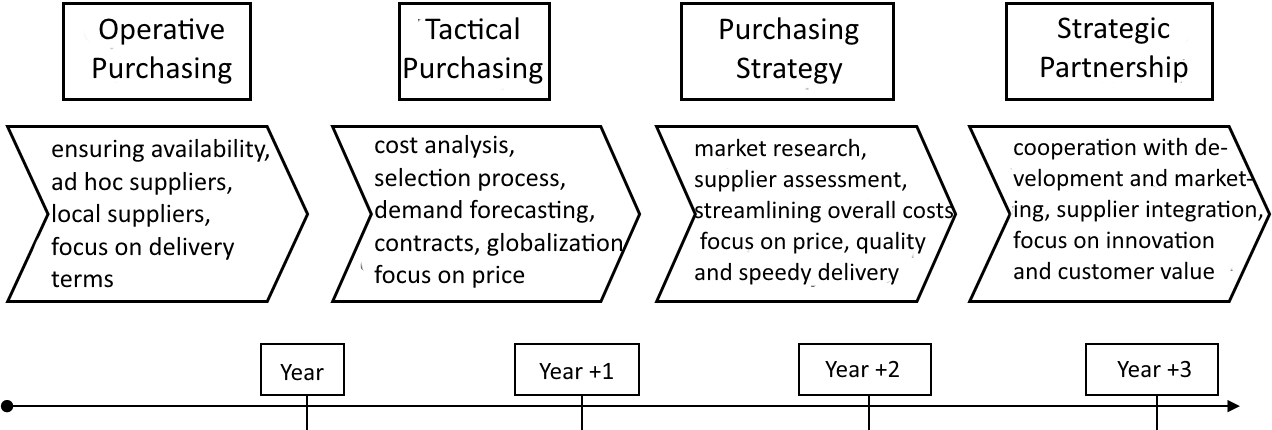

Transition from Operative Purchasing to Strategic Partnership Purchasing (adapted from Červený, Hanzelková, Keřkovský, Němeček, 2013)

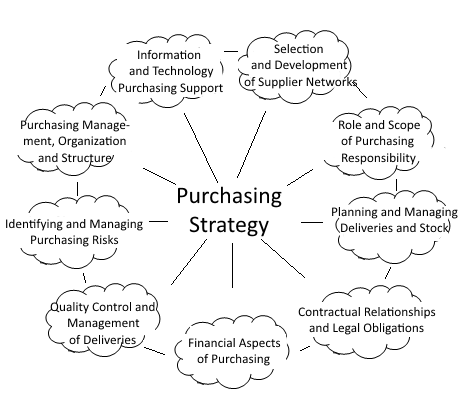

Transition from Operative Purchasing to Strategic Partnership Purchasing (adapted from Červený, Hanzelková, Keřkovský, Němeček, 2013) Purchasing Strategy (Červený, Hanzelková, Keřkovský, Němeček, 2013), own elaboration

Purchasing Strategy (Červený, Hanzelková, Keřkovský, Němeček, 2013), own elaboration