4.4.2. Additional Information

Spatial Arrangement of Production

In terms of the physical, special organization of production, a company can choose one of four basic arrangement models: fixed position of the product, technological arrangement, cellular arrangement, and material arrangement.

If we opt for “fixed position of the product” spatial arrangement, transforming resources shift towards transformed resources, all necessary aspects of production must “come” to the product. This method is applied in the construction sector, production of large units i.e. in the shipping industry etc.

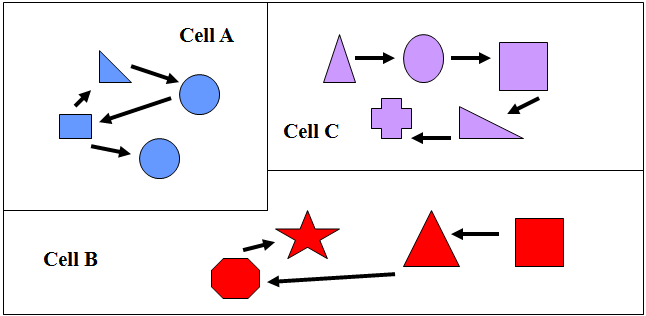

Cellular arrangement involves grouping workstations (cells) responsible for certain stages of the production process in one area, without transferring the product between operations. Each “cell” is responsible for the production of its own “family” of components or products.

Cellular Arrangement of Production (Žufan, 2011a)

Material arrangement involves arranging workplaces according to production requirements, in order to avoid workplace transfers.

Finding the Center of Gravity and How to Minimize Transport Costs

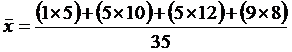

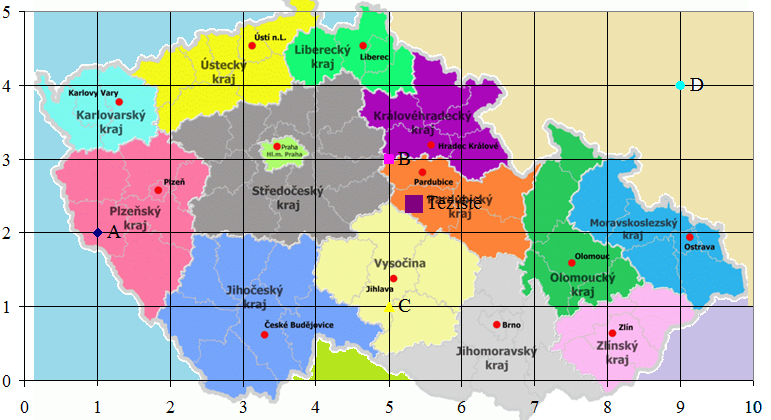

Example: A company runs 4 stores: A, B, C in various locations in the Czech Republic and one (D) in Poland. This company has decided to build a common central warehouse and is looking for the ideal location for it. Selection criteria will consist of transport costs and the aim will be to minimize these costs. Projected weekly deliveries are A-5, B-10, C-12 and D-8. The stores are located in the areas indicated in figure below.

Store Locations

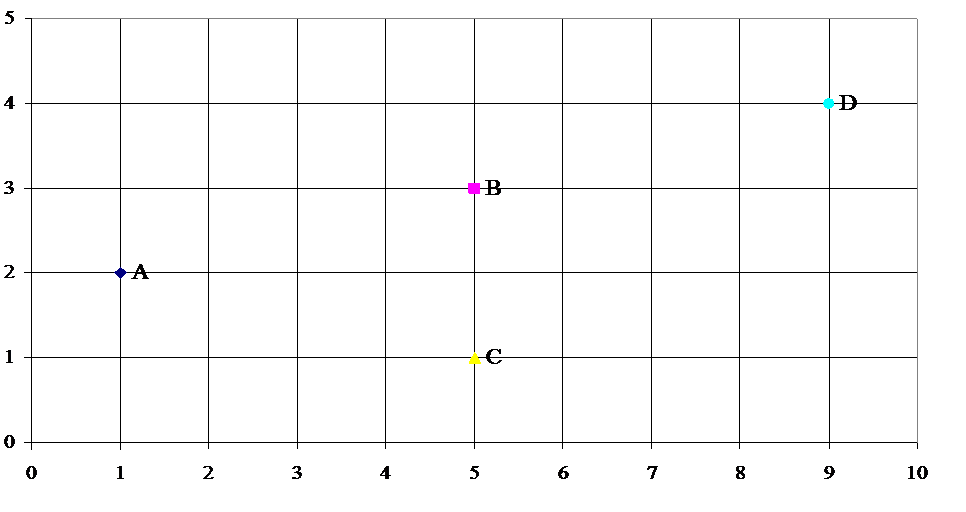

If we transpose the store locations onto a grid, we can find the coordinates and can then easily calculate the center of gravity, i.e. in terms of optimizing transport costs, for the most optimal, central warehouse location. We use a ratio for our calculations.

calculate and we obtain the following coordinates: [5,34; 2,4]

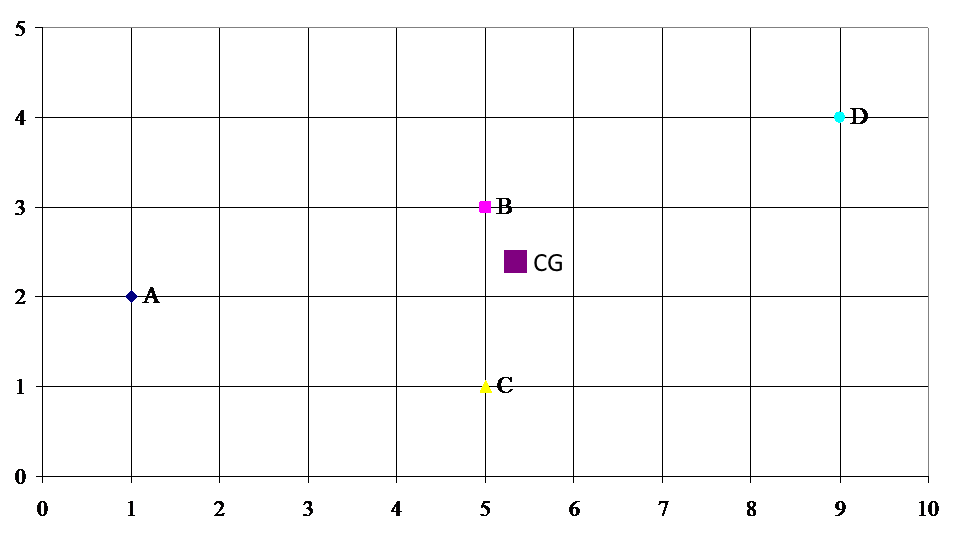

Transposed Store Locations on Grid

Resulting CG Locations

Resulting CG Locations

If we transpose the calculated center of gravity onto the map, we find out that the most optimal location, in terms of optimizing transport costs, would be in the Czech Republic on the border of the Pardubice and Vysocina Regions.

It is necessary, however, to take into account that the given solution does not factor in a wide range of other factors, which could significantly impact the resulting location of the central warehouse.